While the United States and China trade blows over the latest extreme ultraviolet (EUV) lithography machines, the multi-billion dollar lasers that print the world’s most advanced computer chips, the United Kingdom has quietly decided to play an entirely different game. Instead of building massive, water-hungry factories on Earth, British engineers are launching them into orbit.

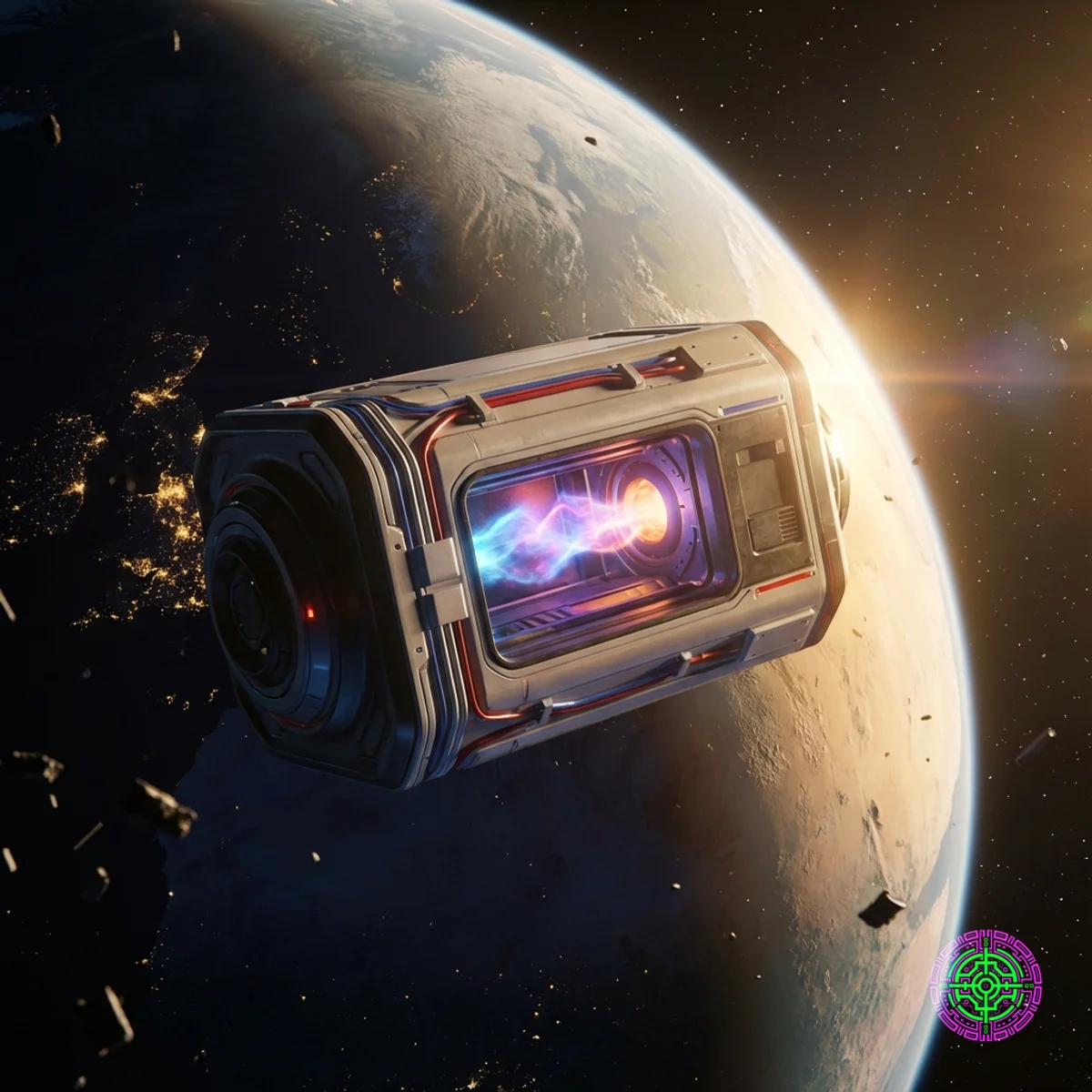

On December 31, 2025, the Cardiff-based startup Space Forge announced a world-first: they had successfully generated plasma aboard their ForgeStar-1 satellite. In a microwave-sized module floating 300 miles above the Earth, a furnace reached 1,000°C, proving that the extreme conditions needed for gas-phase crystal growth can be controlled autonomously in a vacuum. The claim is as audacious as it is technical: semiconductors made in this state could be up to 4,000 times purer than anything made on Earth.

This is the UK’s “Vertical Hail Mary.” It is a strategic pivot away from the crushing capital expense of Silicon Valley-style fabs and toward a niche where British materials science and space heritage might actually give it an edge. As the Cardiff-based cluster prepares for a pivotal 2026, the central question remains: is this a genuine technological leapfrog, or a desperate bet by a nation that has run out of terrestrial options?

The Physics of Perfect Purity

To understand why anyone would spend $50 million on a rocket launch just to heat up a furnace, one must understand the fundamental physics of gravity. On Earth, everything is a compromise. When gallium nitride (GaN) or silicon carbide (SiC) is melted to grow a crystal, two invisible forces ruin the result: convection and sedimentation.

Hot fluids rise, cold fluids sink. This constant churning, known as convection, creates tiny defects—dislocations—in the atomic lattice of the semiconductor. Heavier atoms also settle toward the bottom (sedimentation), leading to an uneven mixture. In the microgravity of orbit, these forces vanish. A “perfect” crystal can be grown where every atom sits exactly where it should.

This isn’t just academic. For the high-power transistors used in Electric Vehicles (EVs) and 5G base stations, perfection equals efficiency. A space-grown crystal handles higher voltages and sheds less heat. If a chip can be made 10% more efficient at converting power, it doesn’t just win a technical award; it fundamentally changes the economics of the 2026 energy grid.

The Cardiff Cluster vs. The Silicon Giants

While the US CHIPS Act is pouring $52 billion into terrestrial manufacturing, the UK’s strategy is significantly more modest and more localized. The “M4 Corridor” in South Wales, stretching from Newport to Cardiff, has become the world’s first Compound Semiconductor Cluster.

In November 2025, the UK government allocated a fresh £10 million to this region. It sounds like pocket change compared to the $100 billion Intel is spending in Ohio, but the focus is different. The UK isn’t trying to make the next iPhone processor; they are trying to own the “next-gen materials” market. By pairing Cardano-esque materials science with Space Forge’s orbital factories, Cardiff is positioning itself as the “Space Fab” capital of the world.

However, the material interest here is as much about political survival as it is about technology. Post-Brexit UK needs a vertical industry it can call its own. The “Vertical Hail Mary” is a way to bypass the global supply chain bottlenecks that leave Britain at the mercy of TSMC or Samsung. If the “means of production” are 300 miles above the Earth, they are technically outside the reach of most trade embargos.

The Downmass Dilemma

The technical “Steel Man” for space manufacturing is compelling, but the engineering constraint that mainstream press often ignores is the “Downmass Dilemma.” Growing a crystal in space is the easy part. Bringing it back through a 3,000-degree re-entry without shattering that perfect lattice is the hard part.

Space Forge is betting on its Pridwen heat shield, a foldable, reusable umbrella designed to slow the satellite down without the violent G-forces of traditional capsules. If Pridwen fails during the scheduled 2026 test flights, the 4,000x purity claim becomes irrelevant. A semiconductor industry cannot be built on “shooting stars” that burn up on approach.

There is also the “Vibration Tax.” Rocket launches are violent. Even if a perfect crystal grows in orbit, the mechanical stress of getting it back to a cleanroom in Cardiff could introduce the very defects regulators and engineers spent millions to avoid.

Digital Twins and the 2008 Echo

History shows this pattern of excitement before. In the 1990s, the Space Shuttle program was marketed on the promise of “perfect drugs” and “orbital factories.” Billions were spent, but the terrestrial competition moved faster. By the time NASA grew a “perfect” protein crystal, Earth-based laboratories had developed computer simulations, or digital twins, and advanced robotics that could mimic the results at 1/1,000th of the cost.

The danger for the Cardiff cluster is that terrestrial wide-bandgap manufacturing is not standing still. Companies like Wolfspeed and ON Semiconductor are already achieving “good enough” yields on 200mm wafers. Unless Space Forge can prove that “4,000x purer” translates into a “10x cheaper” system-level benefit for an EV charger, they risk becoming the Concorde of Semiconductors, a technological marvel that is economically doomed.

The Forward Outlook: Cardiff’s 2026 Deadline

As Q1 2026 begins, the stakes for the UK’s semiconductor strategy are crystalline. The government needs a win to justify its National Semiconductor Strategy, and Space Forge needs to prove that its orbital furnace is more than just an expensive microwave.

Watch for three key milestones in the next 12 months:

- The First Return: Can Space Forge successfully de-orbit a payload and recover it in the Bristol Channel?

- The Yield-Gap Analysis: Will independent benchmarks confirm the efficiency gains of space-grown GaN vs. the latest terrestrial 200mm wafers?

- The Investor Pivot: Will private VC money follow the £10 million government “seed” into Cardiff, or will it continue to flow toward Earth-bound AI logic chips?

The UK isn’t trying to build the next Silicon Valley. They are betting that the next “Valley” isn’t a place on Earth at all. It’s a bold, high-risk strategy that relies on the edge-case physics of microgravity to bypass a century of industrial dominance. If it works, Cardiff becomes the global gateway to the orbital economy. If it fails, it will be remembered as a magnificent, high-tech monument to the UK’s quest for relevance in a world of giants.

Either way, the 1,000-degree furnace is burning. The only question is whether the UK can handle the heat.

🦋 Discussion on Bluesky

Discuss on Bluesky