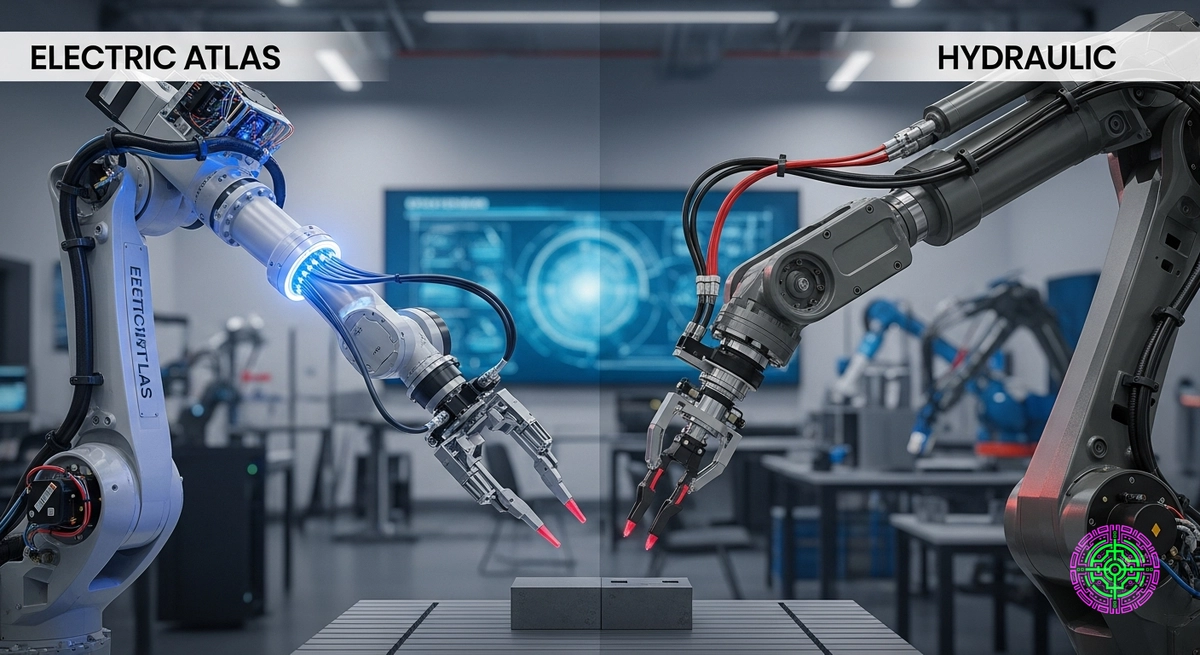

It was the backflip heard around the world. When Boston Dynamics retired their famous hydraulic Atlas robot in early 2024, it wasn’t just a product update; it was a eulogy to an entire era of robotics.

For decades, if you wanted a robot to move with the explosive power of a human athlete:to jump, run, and recover from stumbles:you had only one choice: Hydraulics.

But the new Atlas is fully electric. It’s slimmer, quieter, and strangely, even stronger in some ways. This shift represents a fundamental “crossing of the Rubicon” for engineering. The physics of electric motors have finally caught up to the raw grunt of fluid dynamics.

Here is the technical deep dive into why hydraulics died, and how electric actuators won the war.

The Power Density Trap

To understand why hydraulics ruled for so long, you have to understand Power Density.

Hydraulics are cheats. In a hydraulic system, you have a central pump (the heart) pressurized to 3,000+ psi, and hoses (the arteries) delivering that pressure to actuators (muscles) all over the body.

- The Advantage: The actuator itself can be incredibly small and light because the heavy lifting (generating the pressure) happens elsewhere in the central pump. This gives individual joints a massive power-to-weight ratio.

- The Result: This allowed the old Atlas to explode upward for a backflip. The fluid could dump energy into the joints faster than any battery-electric motor could at the time.

The Problem: The “Leaky Efficiency”

However, hydraulics suffer from what engineers call “parasitic loss.” Keeping that system pressurized at 3,000 psi consumes energy even when the robot is standing still. It’s like keeping a car engine revving at a red light.

- Noise: The pump is loud. Old Atlas sounded like a lawnmower, destroying any chance of working in a quiet office or hospital.

- Leaks: High-pressure fluid finds a way out. A leaked hose means a mess, a slip hazard, and a dead robot.

- Stiffness: Controlling the precise force of a hydraulic piston is difficult. It’s great for “push hard,” but terrible for “gently pick up this egg.”

The Electric Revolution: Torque Density

So, what changed? How did electric motors, historically weak and heavy, suddenly become strong enough to replace hydraulics?

The answer lies in High-Torque Density Motors and Harmonic Drives.

1. The Harmonic Drive (Strain Wave Gear)

Electric motors spin very fast but have low torque. To move a robot limb, you need the opposite: slow speed and massive torque. Enter the Harmonic Drive. It’s a specialized gearbox used in the new Atlas (and Tesla’s Optimus).

How It Works (The Flexspline Physics)

A harmonic drive isn’t like the gears in your car. It uses a flexible metal cup called a Flexspline.

- The Ellipse: An oval-shaped “Wave Generator” sits inside the flexible cup.

- The Deformation: As the generator spins, it deforms the metal cup into an ellipse, forcing the teeth on the outside of the cup to engage with a rigid outer ring.

- The Reduction: Because the cup has fewer teeth than the outer ring, for every full rotation of the motor, the outer ring only moves a tiny fraction.

This allows for massive gear reductions (e.g., 100:1) in a package the size of a donut.

- Zero Backlash: Because the flexible cup is always pre-loaded against the outer ring, there is no “slop” or play. When the motor moves 1 degree, the arm moves precisely 0.01 degrees.

- Torque Density: This mechanism amplifies the weak torque of a high-speed electric motor by 100x without adding the weight of a traditional gearbox.

2. Axial Flux & Gap Radius

Engineers also optimized the motors themselves. By moving to Axial Flux designs (where magnetic flux flows parallel to the axle) or large-diameter “pancake” motors, they increased the “Gap Radius.”

- Physics Rule: Torque = Force × Radius.

- By making the motor wider and thinner (like a pancake), engineers can generate massive torque without needing a heavy gearbox. Atlas uses this to perform backflips without breaking a sweat.

The Control Loop: 1000Hz vs 20Hz

One of the hidden reasons for the switch is Control Theory.

Robots balance by sensing they are falling and moving their legs to catch themselves. The speed at which they can do this is the “Control Loop Frequency.”

- Hydraulics (Low Bandwidth): Fluid is compressible. When you open a valve, it takes milliseconds for the pressure to build up and move the piston. The “Bandwidth” of a large hydraulic system is often limited to 20-30Hz. It’s sluggish.

- Electric (High Bandwidth): Electricity is nearly instantaneous. You can adjust the current in a motor coil 10,000 times a second. The new electric Atlas likely runs control loops at 1000Hz+.

Why It Matters: Imagine trying to balance a broom on your hand. If you can only react once every second (Low Bandwidth), you will drop it. If you can react 100 times a second (High Bandwidth), balancing is easy. The electric Atlas can sustain balances and micro-corrections that the hydraulic version physically could not attempt.

The Battery Math: 1 Hour vs. 4 Hours

The hydraulic Atlas was a sprint runner. The electric Atlas is a marathon runner.

- Hydraulic Efficiency: ~1 Hour Battery Life.

- The pump must run constantly. Even standing still, the robot burns power to maintain pressure.

- Conversion losses: Battery -> Electric Motor -> Pump -> Fluid -> Piston. Every step loses energy (heat).

- Electric Efficiency: ~4 Hour Battery Life (Target).

- Regenerative Braking: When the electric Atlas lowers an arm, the motor turns into a generator, sending power back into the battery. Hydraulics just turn that energy into heat.

- Quiescent Current: Standing still costs almost nothing. The motors engage a brake or hold position with minimal current use.

The Commercial Reality: Why Hyundai Killed It

Boston Dynamics didn’t just switch for fun. They switched because Hydraulics don’t scale.

The Factory Floor Rule

Boston Dynamics is now owned by Hyundai. Their goal isn’t viral YouTube videos anymore; it’s building cars.

- Contamination: You cannot have a hydraulic robot leaking oil onto a pristine car assembly line or near a paint shop.

- Maintenance: A hydraulic robot requires a specialized technician to fix a seal or bleed air from the lines. An electric robot is modular; if a joint fails, you unbolt the actuator and swap it in 5 minutes.

- Uptime: The electric Atlas requires a fraction of the maintenance, meaning it can work three shifts a day.

The Trade-off: Flexspline Fatigue

Is the electric Atlas perfect? No. It traded one problem (leaks) for another (metal fatigue).

Remember the Flexspline? That flexible metal cup in the gearbox? It bends into an oval shape thousands of times a minute.

- Metal Fatigue: Just like bending a paperclip back and forth until it snaps, the metal in a harmonic drive has a finite life limit.

- The “Ratchet” Risk: If the robot tries to lift something too heavy, the flexible teeth can skip or “ratchet,” permanently damaging the gear.

Engineers manage this with exotic steel alloys and precise S-curves in the tooth profile, but it remains the weak link. A hydraulic piston can withstand a shock load (like dropping a box) by venting a relief valve. A harmonic drive might shatter.

In the short term (2025-2026), the market will split. Hydraulics will remain king in heavy industry (mining, construction) where raw power is the only metric that matters. But for everything else (warehousing, logistics, last-mile delivery), electric is the winner.

The Verdict

The Hydraulic Atlas was a marvel of science:a proof that a machine could move like an athlete. But the Electric Atlas is a product. It is the iPhone to the Hydraulic Atlas’s ENIAC computer.

By solving the torque density problem with axial flux motors and harmonic drives, engineers have created a robot that isn’t just cool to watch:it’s ready to go to work. The age of the fluid-filled machine is over; the age of the silent, electric worker has begun.

🦋 Discussion on Bluesky

Discuss on Bluesky