For twenty years, the promise of green hydrogen has been held hostage by a single, stubborn number: 75%.

That is the approximate efficiency ceiling of standard electrolysis. Whether using Alkaline or Proton Exchange Membrane (PEM) technology, systems lose about a quarter of input energy as waste heat. This inefficiency remains the primary reason why green hydrogen has remained “the fuel of the future”—always promising, never arriving.

If 100 kWh of renewable electricity enters a legacy system, only 75 kWh of hydrogen comes out. At that rate, the economics simply do not work. Renewable electricity is precious. Throwing 25% of it away makes the resulting gas nearly four times more expensive than natural gas.

But that era effectively ended this year.

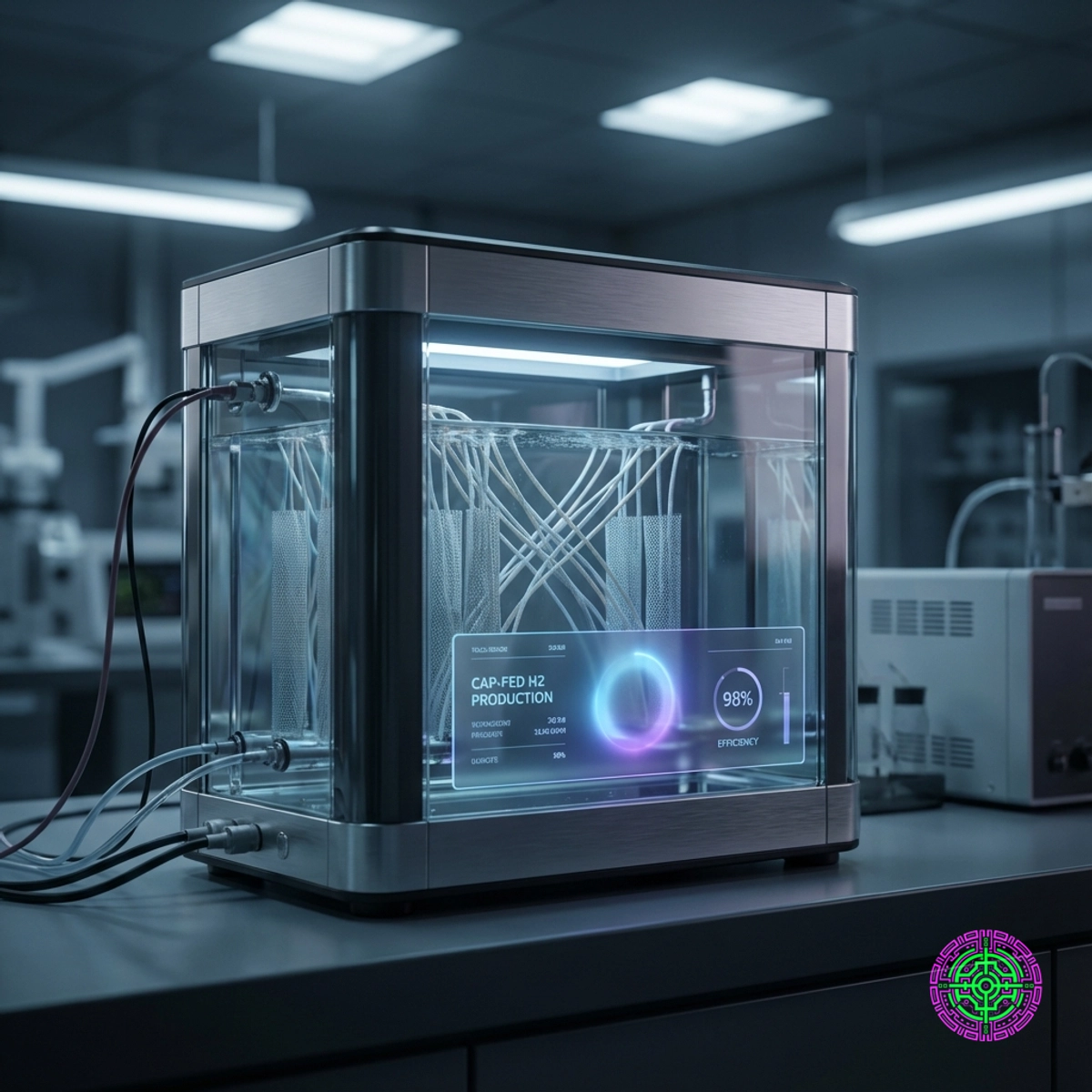

Hysata, a startup spun out of the University of Wollongong in Australia, has introduced a new architecture called Capillary-Fed Electrolysis (CFE). Their peer-reviewed data, published in Nature Communications, confirms a cell efficiency of 95% to 98%.

This is not an incremental 2% gain. This is a physics-breaking leap that brings the energy cost of hydrogen production down to 41.5 kWh/kg, perilously close to the theoretical limit of thermodynamics.

If Hysata can scale this manufacturing, the cost of green hydrogen drops below $1.50 per kilogram. That is the “magic number” where it becomes cheaper to burn clean hydrogen than dirty coal in steel mills.

Here is how they broke the bubble barrier.

The Physics of the “Bubble Problem”

To understand why this breakthrough matters, you must understand why old electrolyzers are so inefficient. The villain in this story is the gas bubble.

In a traditional liquid electrolyte system (Alkaline), two electrodes are submerged in water. When a current runs through them, oxygen forms at the anode and hydrogen at the cathode.

The problem is that these gases form bubbles directly on the surface of the metal electrodes.

The Resistance Trap

Bubbles are non-conductive, effective insulators. When a bubble sits on the electrode, it blocks the liquid electrolyte from touching the metal. This reduces the active surface area available for the reaction and increases the electrical resistance of the cell.

In physics terms, this creates Ohmic resistance. To force the current through this bubbly, chaotic mixture, you have to crank up the voltage.

Higher resistance means requiring more power () to get the same amount of hydrogen. That extra power does not make more gas; it just turns into waste heat. This necessitates the massive cooling infrastructure seen in modern hydrogen plants, giant radiators trying to dump the 25% of energy wasted by bubbles.

Legacy systems try to solve this by pumping the electrolyte through the cell at high velocity to “wash” the bubbles away. But that pumping itself consumes energy, creating a parasitic load that further drags down total system efficiency.

The Solution: Capillary-Fed Electrolysis (CFE)

Hysata’s innovation was to stop fighting the bubbles and instead remove the liquid bath entirely.

Their Capillary-Fed Electrolysis (CFE) cell looks less like a fish tank and more like a lung.

1. The Super-Wicking Separator

Instead of submerging the electrodes, Hysata uses a porous, hydrophilic (water-loving) separator between the anode and cathode. The bottom of this separator sits in a small reservoir of water.

Using capillary action, the same force that pulls water up a paper towel or sap up a redwood tree, the separator draws water up continuously. It saturates the electrodes just enough to facilitate the reaction, but not enough to flood them.

2. The Gas-Permeable Electrode

Because the electrodes are not submerged, one side of them is open to the air (or rather, the collection chamber).

When the water reaches the catalyst and splits, the hydrogen and oxygen gases can escape immediately and freely without having to bubble through a liquid. There is zero bubble resistance because there are no bubbles blocking the current path.

3. Zero Gap, Zero Overpotential

By eliminating the liquid resistance and the bubble effect, the Hysata cell operates with almost zero “overpotential.”

- Standard PEM Cell voltage: ~1.8V - 2.0V

- Hysata CFE Cell voltage: ~1.48V

The thermoneutral voltage of water splitting (the theoretical minimum energy required considering entropy) is 1.48V. Hysata is running effectively at the thermodynamic limit.

The Math of Efficiency

Let’s look at the numbers that have investors and climatologists stunned.

The Lower Heating Value (LHV) of hydrogen is approximately 33.3 kWh/kg. However, production efficiency calculations typically use the Higher Heating Value (HHV) of 39.4 kWh/kg to account for the total energy balance including the latent heat of vaporization.

Common electrolyzers (Alk/PEM) typically consume 50 to 55 kWh of electricity to produce 1 kilogram of hydrogen.

Hysata’s system consumes just 41.5 kWh to produce that same kilogram.

At the cell level, avoiding balance-of-plant (pumps, cooling), they measure 98%.

This 20% difference effectively serves as a 20% discount on electricity. Since electricity makes up 70% of the cost of green hydrogen, this efficiency gain is the single most effective lever for reducing price.

The Economic Impact: The Race to $1.50

Why is everyone obsessed with the price of $1.50/kg?

That is the parity point.

- Grey Hydrogen (from Natural Gas): Costs ~$1.00 - $2.00/kg (highly dependent on gas prices).

- Green Hydrogen (Current PEM): Costs ~$4.00 - $6.00/kg.

- Hysata Target: ~$1.50/kg in the mid-2020s.

At $5.00/kg, green hydrogen is a luxury item, useful only for niche demonstrations or heavily subsidized projects. At $1.50/kg, it becomes economically irrational to use fossil fuels in heavy industry.

The Steel Industry (The 8% Problem)

Steel production accounts for 8% of all global CO2 emissions. Traditional blast furnaces use coal (coke) as a chemical reducing agent to strip oxygen from iron ore.

You cannot decarbonize this with solar panels. You need a chemical reaction. Hydrogen can do it:

The byproduct is water, not CO2. But steel mills operate on razor-thin margins. They cannot absorb a 4x fuel cost increase. Hysata’s technology brings the cost of the green reductant in line with the cost of coal coke.

Simplified Balance of Plant (BoP)

The efficiency gain has a secondary economic benefit: CaPex reduction. Because the cell generates almost no waste heat, a Hysata plant does not need the massive, expensive liquid cooling loops that define a PEM plant.

- Less plumbing.

- Smaller pumps.

- No water circulation systems (only makeup water feed).

This makes the factory simpler and cheaper to build per megawatt of capacity.

Contextual History: The Electrolyzer Wars

To appreciate the “leap,” analysis necessitates looking at the slow crawl that preceded it.

1. Alkaline Electrolysis (1920s - Present) The workhorse. Uses a liquid potassium hydroxide (KOH) electrolyte. Reliable, cheap materials (nickel), but bulky and inefficient. It cannot ramp up and down quickly, making it poor at pairing with variable wind/solar.

- Efficiency: ~65-70%.

2. PEM Electrolysis (1960s - Present) Developed for the Gemini space program. Uses a solid polymer membrane. Compact, handles high pressure, and ramps instantly. However, it requires Iridium, one of the rarest metals on Earth, and operates in a highly acidic environment.

- Efficiency: ~70-75%.

3. Solid Oxide (SOEC) Uses ceramics at extremely high temperatures (700°C+). Very efficient electrically but requires a massive external heat source. It is fragile and takes hours to turn on or off.

- Efficiency: ~85%+ (thermal dependent).

4. Capillary-Fed (Hysata) This represents a new “fourth state.” It combines the cheap materials of Alkaline (no Iridium required) with the efficiency of Solid Oxide, but operates at mild temperatures (80°C).

It solves the Intermittency Matching problem. Because it creates so little heat, it can be driven hard (high current density) when the sun is shining without overheating. This allows operators to run the plant at 5x capacity during peak solar production hours.

Forward-Looking Analysis: 2026 and Beyond

Hysata is currently building its manufacturing headquarters in Port Kembla, Australia (a major steel hub). They are backed by the Clean Energy Finance Corporation (CEFC) and huge heavy industry players.

The Hurdles to Scale Despite the physics working, the challenge is now manufacturing engineering.

- Membrane Consistency: The porous separator must be manufactured perfectly. If the pores are too small, water doesn’t wick fast enough. If too large, they flood.

- Stack Assembly: Assembling thousands of these cells into a 100MW (megawatt) stack without leakages is a non-trivial plumbing challenge.

The “Green Premium” Collapse If Hysata hits its targets by 2026/2027, the global hydrogen roadmap accelerates by about a decade. Most projections (IEA, BloombergNEF) didn’t expect $1.50/kg until the mid-2030s.

Forecasts suggest the first major deployments will effectively appear not in cars (EVs have won that war), but in ammonia plants and steel mills. Australia, with its limitless solar potential, is positioning itself to be the “Saudi Arabia of Green Hydrogen,” exporting the gas (as Ammonia) to energy-starved Japan and Korea.

The Hysata cell proves that the barrier to a hydrogen economy wasn’t money or political will. It was bubbles. And now, they are gone.

🦋 Discussion on Bluesky

Discuss on Bluesky