Key Takeaways

- The Physics: Gravity is a “contaminant.” It causes convection and sedimentation, which ruin delicate crystal structures during manufacturing.

- The Product: Varda Space Industries has successfully manufactured Ritonavir (an HIV drug) in orbit, proving that zero-G yields purer, more effective crystals.

- The Future: Beyond drugs, ZBLAN fiber optics made in space are up to 100x clearer than Earth-made glass, promising to revolutionize the internet backbone.

For the last 60 years, we went to space to look at things. Satellites looked down at Earth; telescopes looked out at the stars.

Now, we are going to space to make things.

The era of “Made in China” or “Made in USA” is ending. The next label on your prescription bottle might read “Made in LEO” (Low Earth Orbit).

The Gravity Problem

On Earth, gravity serves as a constant, invisible spoon that stirs everything up.

- Convection: Heat rises, cold creates currents.

- Sedimentation: Heavy particles sink to the bottom.

If you are trying to grow a perfect crystal—essential for many drugs and fiber optics—this stirring causes defects. It’s like trying to build a house of cards in a wind tunnel.

In microgravity, these forces disappear. You can control the position of every molecule with absolute precision.

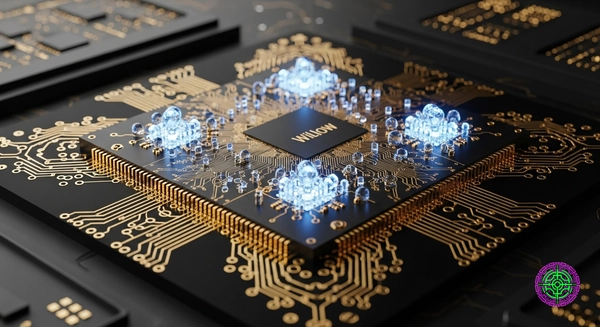

The Varda Breakthrough

Varda Space Industries, founded by Will Bruey (ex-SpaceX) and Delian Asparouhov (Founders Fund), isn’t building a space station with astronauts. They are building unmanned space factories.

Their W-Series capsules are small, autonomous labs.

- Launch: They hitch a ride on a SpaceX Falcon 9.

- Cook: Once in orbit, the capsule activates. It melts the raw materials and slowly cools them to crystallize the product in perfect stillness.

- Return: The factory becomes a reentry capsule, slamming through the atmosphere at Mach 25 to deliver the finished product to a landing site in Utah.

The Return Capsule Physics

Getting to space is hard. Getting back is harder.

Most satellites burn up on reentry. Varda’s W-Series capsule has to survive temperatures of 3,000°F (1,650°C) while protecting delicate crystal payloads.

- The Heat Shield: It uses a PICA (Phenolic Impregnated Carbon Ablator) shield, similar to what SpaceX uses on Dragon. As it hits the atmosphere, the material slowly burns away, carrying the heat with it.

- The Braking: It decelerates from 17,500 mph to 0 mph in under 20 minutes. The G-forces are immense, but crystals are surprisingly resilient to steady acceleration—unlike the chaotic vibration of a rocket launch.

Regulatory Hurdles: The FAA Battle

Varda’s first mission, W-1, was a technical success but a regulatory nightmare.

The capsule was stuck in orbit for months, not because of a glitch, but because the FAA (Federal Aviation Administration) wouldn’t authorize the landing.

- The Issue: The US military has test ranges in Utah for missiles, but letting a private company drop a 200kg capsule from orbit into a military zone was unprecedented.

- The Precedent: Eventually, a license was granted (Part 450), marking the first time a private company was authorized to land a spacecraft on US soil. This legal framework is just as important as the PICA heat shield for the future of the industry.

Future Roadmap: Semi-Automated Outposts

Currently, Varda builds disposable satellites. The next step is reusability.

Imagine a permanent “manufacturing hub” in orbit:

- A Starship launches a cargo container of raw materials.

- Robotic arms dock it to the station.

- The factory processes the batch.

- The finished product is loaded into a small reentry pod and fired back to Earth.

- The station stays in orbit, waiting for the next delivery.

This eliminates the cost of launching a new factory every time, reducing the price-per-kilogram even further.

The Economics of Reusability

“But isn’t space expensive?” Yes, but the math is changing rapidly.

The Launch Cost Curve

- Space Shuttle (1981): ~$54,500 per kg.

- Falcon 9 (2016): ~$2,720 per kg.

- Starship (Target): ~$100 per kg.

When launch costs drop by 99%, business models that were previously “sci-fi” become “venture-backable.”

The Varda Math

Varda doesn’t need Starship to be profitable. They are targeting high-value goods where the mass is low but the price is astronomical.

- Cost: Launching a 300kg capsule might cost $1-2 million.

- Revenue: If that capsule returns with 20kg of perfect Ritonavir crystals (value >$50M), the margins are better than software.

Orbit vs. The Moon: Where should we build?

While Varda is focusing on Low Earth Orbit (LEO), others like Blue Origin look to the Moon.

- LEO (Varda): Best for Microgravity. You are in freefall. Perfect for crystals and organ printing.

- The Moon (Blue Origin): Has gravity (1/6th Earth). Bad for crystals, but great for heavy industry. You can mine lunar regolith for silicon, aluminum, and oxygen to build massive structures in space, rather than launching them from Earth.

Varda is the “short-term” play (High-value pharma). The Moon is the “long-term” play (Heavy industrial base).

Beyond Pharma: The Crystal Internet

The other holy grail is ZBLAN.

It’s a type of fluoride glass that is theoretically 100x more transparent than the silica glass used in today’s fiber optic cables.

- On Earth: Gravity causes tiny crystals to form in the glass as it cools, making it cloudy and useless for long distances.

- In Space: It cools perfectly clear.

A ZBLAN cable could span the Atlantic Ocean without needing “repeaters” (expensive amplifiers) every 50 miles. A single kilogram of this space-fiber could replace tons of traditional infrastructure.

The Economics

“But isn’t space expensive?”

Yes, but the math is changing.

- Launch Cost: SpaceX has lowered the cost to orbit to ~$2,500/kg.

- Product Value: Keytruda (a cancer drug) is worth ~$100,000/kg.

When the product is worth 40x its weight in gold, the cost of the rocket is a rounding error. As Starship comes online, this margin will only explode.

We are witnessing the birth of the off-world industrial base. The factory of the future isn’t in Detroit or Shenzhen. It’s 250 miles up.

The Human Element: Astronauts as Factory Workers?

For now, Varda is fully autonomous. But what happens when things break? The next phase of space manufacturing involves human-tended outposts.

- Axiom Space: Building a commercial module for the ISS (and eventually a standalone station) specifically for research and manufacturing.

- Voyager Space (Starlab): Another commercial station planned to replace the ISS.

There is a future where “Factory Technician” is a job title that requires a spacesuit. We aren’t just sending scientists anymore; we are sending welders, machine operators, and quality control engineers.

The Global Race: China is Watching

It’s not just US startups. China’s Tiangong space station is already running hundreds of microgravity experiments. The race for orbital manufacturing dominance is the new Space Race. Who controls the “means of production” when the production line is in orbit?

- US Strategy: Private sector led (Varda, SpaceX, Blue Origin).

- China Strategy: State-led (CNSA).

The winner controls the supply chain for next-gen pharmaceuticals and computing materials.

🦋 Discussion on Bluesky

Discuss on Bluesky