Key Takeaways

- The Concept: Instead of putting a heavy battery inside a heavy steel frame, you make the frame out of battery material.

- The Material: Carbon fiber is the key. It is strong enough to be a chassis and conductive enough to be an electrode (anode).

- The “Massless” Effect: Even though the battery chemistry itself has lower energy density than Li-Ion, the system weight drops drastically because you delete the steel frame.

- Status: Swedish startup Sinonus (a Chalmers spin-off) is moving this from “lab curiosity” to commercial reality in 2025.

In every vehicle ever built—from the Model T to the Tesla Model S—there is a fundamental inefficiency.

It’s called “parasitic structure.”

The fuel tank (or battery pack) is a heavy box that does nothing but hold energy. The chassis is a heavy frame that does nothing but hold the box. You are using energy to move the frame that carries the box that holds the energy.

What if they were the same thing?

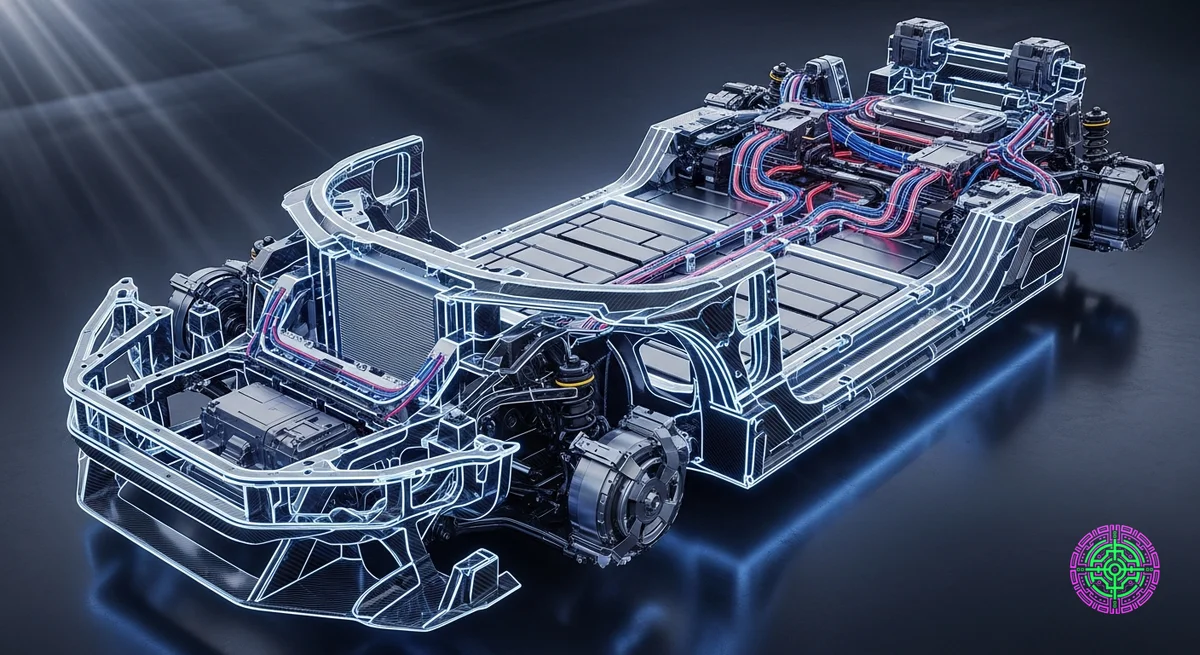

This is the promise of Structural Batteries, also known as “Massless Energy Storage.” By engineering carbon fiber composites that can store electrons while bearing load, engineers are deleting the “dead weight” of the battery pack entirely.

The Physics: How Cladding Becomes an Anode

To understand how a piece of a car’s frame can store power, you have to look at the microstructure of carbon fiber.

1. The Dual Role of Carbon

Standard lithium-ion batteries use graphite as the anode (negative side). Carbon fiber is essentially organized graphite.

- Mechanical: It’s stiff and strong (70 GPa stiffness, comparable to aluminum).

- Electrical: It has a microstructure that allows Lithium ions to intercalate (cradle) within the fibers.

2. The Architecture

In a structural battery:

- The Anode: The structural carbon fibers of the chassis.

- The Cathode: A lithium-rich metal oxide coated onto aluminum foil, reinforced with fiberglass for stiffness.

- The Electrolyte: This is the tricky part. It can’t be a liquid (or the frame would be squishy). It is a “structural electrolyte”—a solid polymer loaded with liquid salts that transfers ions while gluing the whole thing together like a super-strong resin.

The Math: Why 30 Wh/kg Beats 250 Wh/kg

Critics point out that structural batteries have a low energy density—currently around 30-60 Wh/kg, compared to 250+ Wh/kg for a top-tier Tesla cell.

“Why would I want a battery that is 5 times worse?”

Because you aren’t doing the math right. You have to look at the System Level. If you use a structural battery, you delete the steel frame, the aluminum casing, the plastic module holders, and the cooling plates.

- Traditional Car: 2000kg Car + 500kg Battery = 2500kg Total.

- Structural Car: 1500kg Car (Frame is the Battery).

Even if the battery is less efficient per kilogram, the car itself is so much lighter that the range stays the same or increases. The battery effectively has “negative mass” because it replaces a heavier structural part.

Application: Who is Doing It?

1. Sinonus (The Commercial Leader)

Spun out of Chalmers University in Sweden, Sinonus is the first company aggressively commercializing this. In 2025, they are targeting consumer electronics (imagine a laptop where the lid is the battery) before moving to EVs.

2. Tesla (The Half-Step)

Tesla’s “Structural Battery Pack” (using 4680 cells) is often confused with this tech. It is a half-step.

- Tesla: Glues standard cylindrical cells into a block to make the block stiff. The cells help the structure.

- True Structural Battery: There are no cells. The fiber itself is the battery.

3. Aerospace (The Holy Grail)

Electric planes are currently impossible because batteries are too heavy. Structural batteries are the fix. If the fuselage and wings of a plane can double as fuel storage without adding weight, electric aviation becomes physics-compliant for the first time.

Challenges & Limitations

- Stiffness vs. Energy: There is a seesaw trade-off. If you make the electrolyte stiffer (better frame), ions move slower (worse battery). If you make it conductive (better battery), it gets softer (worser frame). Finding the “Goldilocks” polymer is the active research front.

- Cycle Life & Swelling: Batteries swell when they charge. You do not want your car chassis to expand and contract every time you plug it in. Engineers are developing rigid lattice structures that contain the swelling internally.

- Safety: If you crash, your frame is literally energetic material. However, research suggests structural batteries might actually be safer—they don’t have the volatile liquid electrolytes that cause “thermal runaway” fires in standard EVs.

What’s Next?

Short-Term (2026)

Expect to see “Structural Power” in drones and high-end laptops. A drone where the carbon fiber arms are the battery can fly 20% longer.

Long-Term (2030+)

The “Unibody of Power.” We will see EV skateboards printed as single, solid-state structural batteries. The concept of “changing a battery” will disappear; the car is the battery.

The Bottom Line

We are witnessing the merger of two disciplines: Civil Engineering and Chemical Engineering.

For a century, we treated energy storage as cargo—something to be hauled. Structural batteries treat energy storage as anatomy. It is the muscle and the bone wrapped into one.

🦋 Discussion on Bluesky

Discuss on Bluesky