For the last decade, the biggest question in the EV world was “How far can it go?” Range anxiety was the primary psychological barrier. But as we cross the 300-mile standard in mass-market vehicles, the question is shifting. The new metric that matters isn’t Total Range; it’s Miles Per Minute of charging.

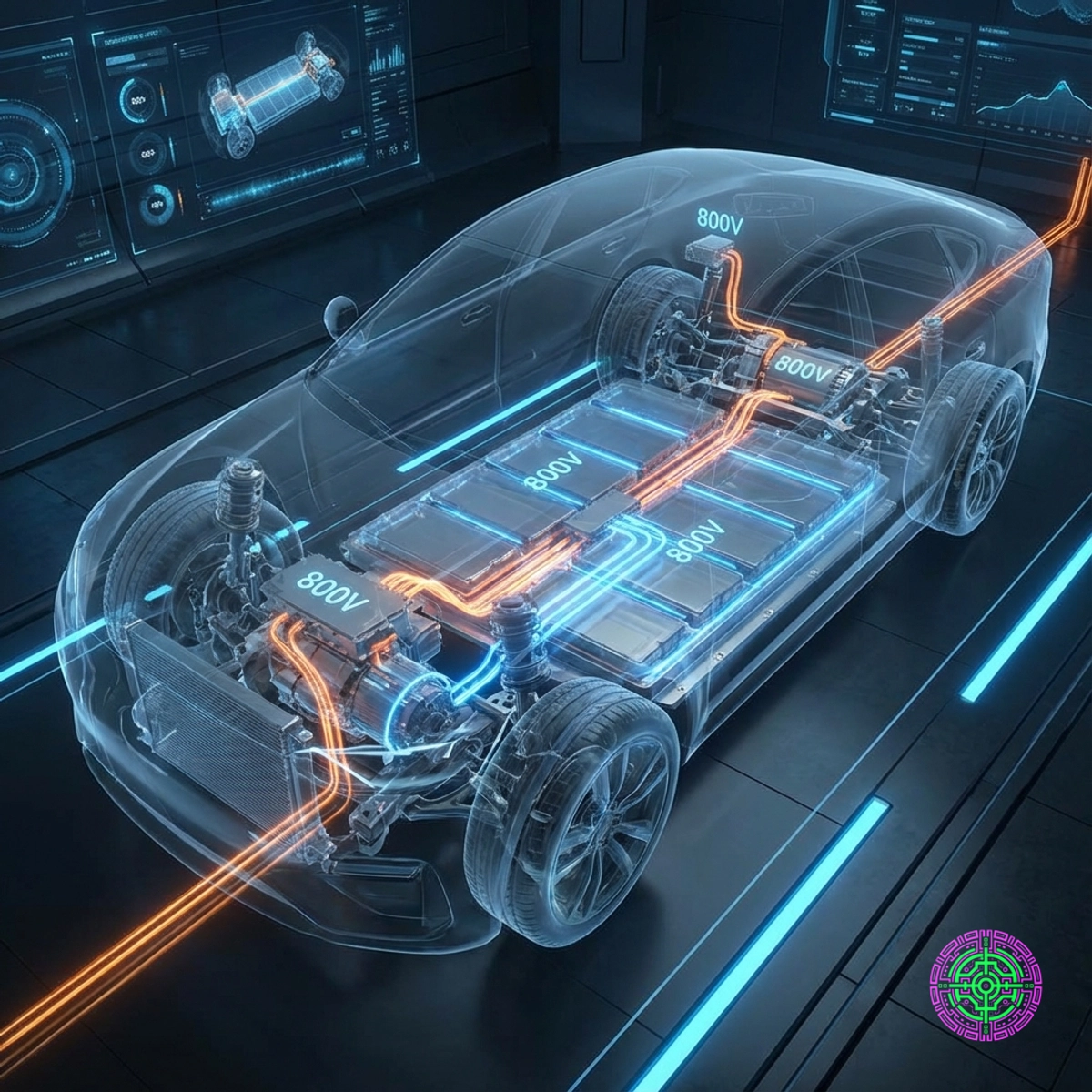

In 2025, a new standard has emerged that makes the previous generation of EVs look like they are refilling through a straw. It is the 800V Architecture, and it is not just a marketing number—it is a fundamental shift in the physics of energy transfer.

The History: From 12V to 800V

To understand the magnitude of this shift, we need to look at the voltage evolution.

- 12V: The standard lead-acid battery for ICE cars (lights, radio, starter).

- 100V-300V: Early hybrids like the Toyota Prius.

- 400V: The “Tesla Standard.” When the Model S launched in 2012, 400V was revolutionary. It allowed for Supercharging at 120kW, then 250kW. It has been the industry benchmark for a decade.

- 800V: The new frontier. First debuted by the Porsche Taycan, now democratized by Hyundai/Kia E-GMP platform.

Why jump? Why not 1000V or 2000V? The answer lies in the component ecosystem—capacitors, inverters, and isolation materials are widely available for industrial applications up to 1200V, making 800V the sweet spot for automotive performance without custom-fabricating every single chip.

The Physics Problem: Joule Heating

To charge a battery faster, you have to push more power (P) into it. The formula for electrical power is simple: P = V × I (Power = Voltage × Current)

In the “legacy” 400V standard, to get 250 kW of charging speed (fast charging), you have to push a massive amount of current: 250,000 W / 400 V = 625 Amps

625 Amps is an enormous amount of current. For context, a typical arc welder uses 100-200 Amps. Pushing 600+ Amps through a cable creates a major problem: Heat.

Heat generation in a cable is determined by Joule’s Law: Q ∝ I²R (Heat is proportional to the Square of the Current)

This is the killer. If you double the current to charge faster, you don’t generate twice the heat—you generate four times the heat. At 400V, cables were becoming so hot they needed active liquid cooling systems (like Tesla’s V3 Superchargers). Connectors were reaching their thermal melt limits. We hit a physics wall. You physically couldn’t build a cable light enough for a human to lift that could carry more amperage without melting.

The 800V Solution: The Thermodynamics Hack

The engineering solution is elegant: Double the Voltage.

By moving from 400V to 800V, you can deliver the same 250 kW of power with half the current. 250,000 W / 800 V = 312 Amps

- Half the Current means 1/4th the Heat (because of the I² law).

This thermal headroom fundamentally changes the charging curve.

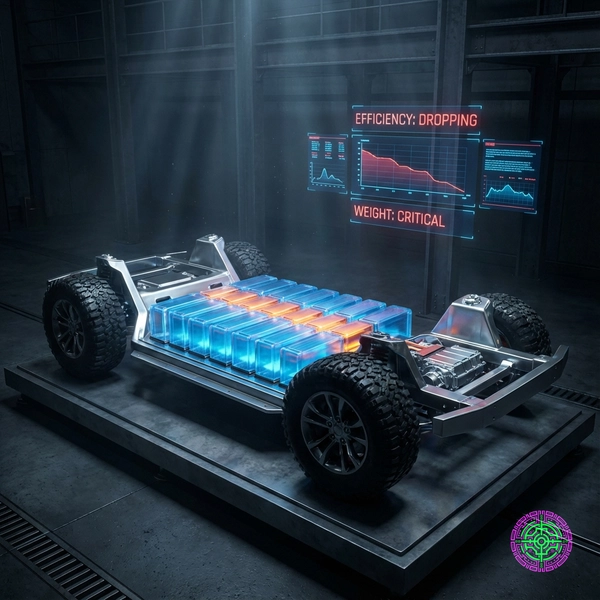

- 400V Challenge: A Tesla Model Y might hit 250kW for a few minutes, but then the cable (or the battery pack) gets too hot, and it throttles down to 150kW, then 100kW. The “average” speed is much lower than the “peak.”

- 800V Advantage: Cars like the Porsche Macan EV, Kia EV9, and the Hyundai Ioniq 5 can sustain peak charging speeds for much longer. They can flatline at 230kW+ all the way to 80% state of charge.

The result? 10% to 80% charge in 18 minutes. That is a bathroom break and a coffee, not a sit-down meal.

The “Copper Diet” and SiC Inverters

The benefits of 800V go deeper than just charging speeds. It fundamentally changes the car’s weight and efficiency.

1. The Weight Savings

Because current (I) is lower, the cables pushing that electricity around the chassis can be thinner.

- 400V System: Needs thumb-thick copper cables (00 AWG or larger) to safely handle 600A bursts.

- 800V System: Handles the same power with 300A, allowing for 30% lighter wiring harnesses.

Copper is heavy (density of 8.96 g/cm³) and expensive. Shaving 20-30kg of copper wiring out of a vehicle reduces curb weight, which in turn increases range and handling performance.

2. The Silicon Carbide (SiC) Key

This voltage jump wouldn’t work without a material breakthrough: Silicon Carbide (SiC).

Traditional Silicon switches (IGBTs) used in older inverters lose efficiency at high voltages—they get too hot and switch too slowly. They are like a leaky faucet. SiC semiconductors, however, love high voltage. They are a “wide bandgap” material.

- Higher Temperature: Can operate at much higher temps without failing.

- Faster Switching: Can switch on/off thousands of times faster than Silicon.

- Efficiency: Up to 99% efficiency.

An 800V SiC inverter doesn’t just handle the power; it wastes less of it. This directly improves the car’s driving range by 5-10% simply because less energy is lost as waste heat in the conversion from Battery (DC) to Motor (AC).

The Infrastructure Reality Check

If 800V is so good, why isn’t everyone doing it?

- Cost: SiC chips are still significantly more expensive than Silicon IGBTs, though prices are falling.

- Compatibility: If an 800V car plugs into an older 400V charger, it needs a way to “step up” the voltage.

- The Porsche Method: An expensive onboard DC/DC booster.

- The Hyundai Method: Using the motor windings themselves as a booster coil (brilliant engineering).

- The GM Method: Switching the battery pack from “Series” to “Parallel” (mechanically complex).

The 2025 Landscape

The “800V Club” was once exclusive to the $150,000 Porsche Taycan. In 2025, it is the new mass-market standard.

The Leaders:

- Lucid Air: 900V+ architecture, arguably the most efficient EV powertrain on earth.

- Porsche/Audi (PPE Platform): Macan EV, Q6 e-tron. Bringing luxury performance to 800V.

- Hyundai/Kia (E-GMP): The heroes of democratization. Ioniq 5, Ioniq 6, EV6, EV9. Bringing 18-minute charging to the $40k-$50k segment.

If you are buying an EV in 2025, check the voltage. A 400V car isn’t obsolete, but it will spend twice as long at the charger as its 800V cousin. Physics doesn’t negotiate.

🦋 Discussion on Bluesky

Discuss on Bluesky